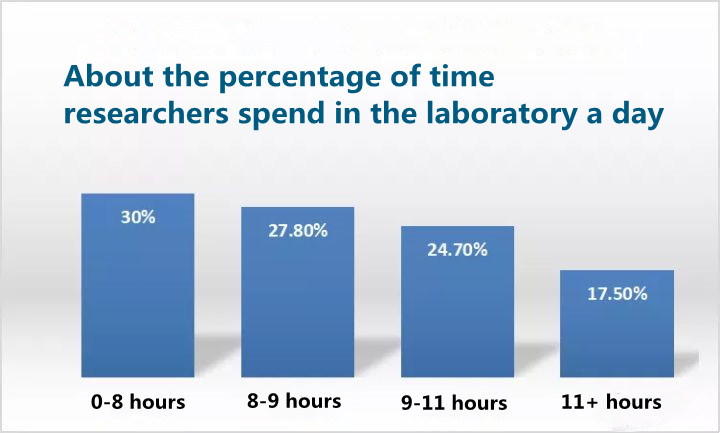

Lo mfanekiso ungasentla luhlalutyo lwamanani epesenti yexesha elichithwe kwibhubhoratri ngabaphandi. Phakathi kwazo, ama-70% exesha elichithwe kusenziwa imifuniselo, ukufunda uncwadi, nokubhala iingxelo elabhoratri lingaphezulu kweeyure ezisibhozo, kunye ne-17.5% yovavanyo.“izigebenga”kuphando lwezenzululwazi ukufikelela ngaphezu 11 iiyure. Ke ulenza njani ixesha lokucoca iibhotile zeglasi ezisetyenziswa kuvavanyo lwemini? Indlela yokuqinisekisa ukuba emva komhla wophando oluphezulu lwenzululwazi, iibhotile ezihlanjiweyo kunye nezitya zinokufikelela kumgangatho wokucoca, ukuze ungachaphazeli uvavanyo olulandelayo?

Beka phantsi ibrashi kunye nebhotile esandleni sakho, cima i-faucet, kwaye ujonge iwasha yebhotile, uya kuzisola ngokungasebenzisi iwasha yebhotile ngokukhawuleza!

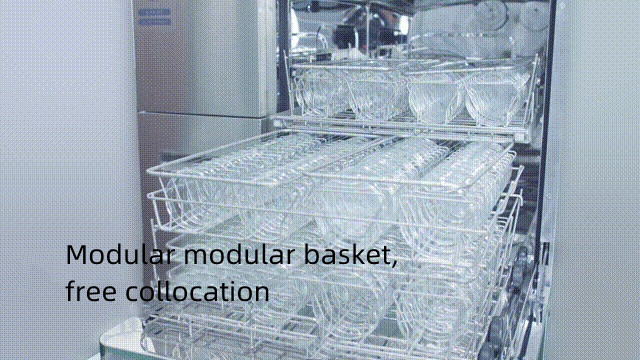

01 Uyilo lwemodyuli yemodyuli Unikezelo lwasimahla

Umbuzo: Sineentlobo ezininzi zeebhotile zaselabhorethri, ezifana neeflasks zevolumetric, iibhekile, iibhotile zesitofu zesampuli, njl.Iwasha yeglasi ezenzekelayoukuhlangabezana nezi mfuno zokucoca ngaxeshanye?

Impendulo: Ewe kunjalo, iIwashi yeglasi yeLabhoratriyamkela uyilo lwemodyuli. Imodyuli yokucoca inokutshintshwa ngokungaqhelekanga ngokohlobo lweebhotile eziza kuhlanjululwa, kunye neemeko ezahlukeneyo zokucoca, inkqubo ineenkqubo eziqingqiweyo ze-35 ezakhelwe ngaphakathi kunye namakhulu eenkqubo zokwenza ngokwezifiso. Inkqubo inokufezekisa ngokwenene nantoni na oyifunayo, kunye nokwabiwa kwamahhala.

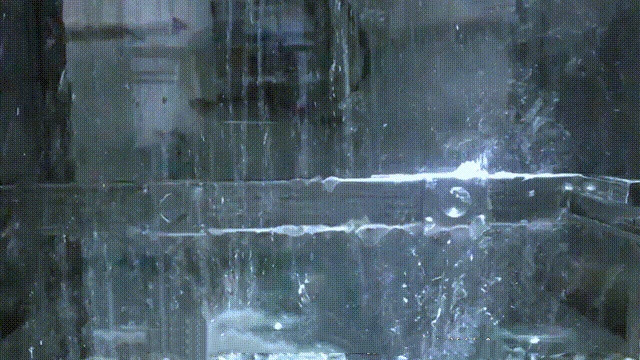

02 Ukudityaniswa kwengalo yokutshiza kunye nenaliti enye ukuya kwenye yokucoca ngaphandle kwe-engile efileyo

Umbuzo: Yintoni indlela yokucoca yeUmatshini wokucoca iglasi? Kwaye uqinisekisa njani ukuba icocekile?

A: Amagumbi aphezulu kunye nasezantsi axhotyiswe ngeengalo ezimbini ezijikelezayo ze-360 ° zokucoca umphezulu webhotile, kwaye imibhobho yesitofu enye ukuya kwenye isetyenziselwa ukucoca umphezulu wangaphakathi webhotile, ukuze kufezekiswe konke- ukucocwa okujikelezayo kwendawo yangaphakathi nangaphandle yebhotile. . Ungaqinisekisa njani ukuba inokucocwa? Inkqubo yokucoca ibandakanya ukuhlamba kwangaphambili, ukuhlamba okuphambili kwe-alkali, ukungathathi hlangothi kwe-asidi, ukuhlanjululwa kwamanzi ahlambulukileyo, ukujonga okukhethiweyo kwe-conductivity kunye nenkqubo yomshicileli, ukubonelela ngedatha yexesha langempela, ukwenzela ukuqaphela ukucocwa okusebenzayo kweebhotile kunye nezitya kunye nokurekhoda kwedatha kunye nokulandelwa.

I-03Ulawulo lwe-Microcomputer kunye nokuchonga itekhnoloji yokuchonga igcina kakhulu iindleko zokucoca

Umbuzo: Umatshini omkhulu ngolo hlobo kufuneka ubize kakhulu emanzini nakumbane, akunjalo?

Impendulo: Emva komlinganiselo wobugcisa, iziphumo zimi ngolu hlobo lulandelayo (xa amakhulu eebhotile zilayishwe ngokupheleleyo):

1. Ukusetyenziswa kwamandla (ubushushu bamanzi bungekho ngaphantsi kwe-15℃):

Imodi esemgangathweni: ukusetyenziswa kwamandla yi-3.12 kWh, kwi-1.00 yuan / kWh, ixabiso yi-3.12 yuan;

Imowudi yokuhlamba yonke indawo: ukusetyenziswa kwamandla yi-4.25 degrees, ngokwe-1.00 yuan / degree, ixabiso yi-4.25 yuan.

2. Ukusetyenziswa kwamanzi:

Imodi yokucoca eqhelekileyo: 40L, kwi-2.75 yuan / ton, ixabiso yi-0.11 yuan; (ibalwe ngokupheleleyo ngamanzi etephu)

Imodi yokucoca ngokubanzi: 60L, kwi-2.75 yuan / ton, ixabiso yi-0.165 yuan; (kubalwa ngokupheleleyo ngamanzi etephu)

3. Iarhente yokucoca:

Malunga ne-9 yuan yokucoca enye

4. Isishwankathelo seendleko:

Ukucoca okusemgangathweni, ixesha ngalinye ngu-3.12 + 0.11 + 9.00 = 12.23 yuan / ixesha;

Ukucoca ngokubanzi, ixesha ngalinye 4.25 + 0.165 + 9.00 = 13.415 yuan / ixesha

Xa kuthelekiswa nokucoca ngesandla, iindleko zokucoca umatshini zingagcinwa malunga ne-1/2.

I-04In-situ yokomisa kunye nomsebenzi wokuvula umnyango ngokuzenzekelayo ugxininisa uyilo olwenziwe ngumntu

Umbuzo: Ngaba kukucoca nje? Ngaba kukho naziphi na iimpawu eziqaqambileyo?

Impendulo: Ukuze kuhlangatyezwane neemfuno zabasebenzisi abafuna ukomiswa emva kokucoca, izixhobo zinokuxhotyiswa nge-in-situ drying function. Emva kokucoca, inokungena ngokuzenzekelayo inkqubo yokomisa njengoko ifunwa, kwaye ixhotyiswe ngekotoni yokucoca i-HEPA ephindwe kabini ukuze iqinisekise ngakumbi ukomisa. Ukucoceka komoya kwinkqubo. Emva kokucoca kunye nokumisa, nge-teknoloji ye-ITL ye-induction, umnyango uya kuvula ngokuzenzekelayo kwindawo ethile ngomzuzu omnye, ukunciphisa izinga lokushisa kwi-cavity emva kokucoca kunye nokumisa. Thintela abasebenzi ukuba bangatshiswa ngumoya oshushu, uqaqambisa uyilo olwenziwe ngumntu.

isishwankathelo

Indlela eya kuphando lwezenzululwazi inde, kwaye iWasher yeBottle yeGlasi eZizimelayo ilapha!

Ixesha lokuposa: Apr-18-2022