Yazisa umgaqo womatshini wokuhlamba iglasi yelabhoratri kunye nemisebenzi esixhenxe yeenkqubo ezintathu ezinkulu

I-Automatic Glassware Washer yisethi yokucoca ngokuzenzekelayo, umsebenzi wokomisa njengenye yeemveliso zobuchwepheshe obuphezulu.Inokuthi ithathe indawo yokucocwa kwencwadana kunye nokomiswa kweeglasi ezahlukeneyo zelabhoratri, iindidi zeenkqubo ezicwangcisiweyo, indlela yokucoca iqhosha elilodwa linciphisa kakhulu umthwalo ongasebenziyo wabaphandi bezenzululwazi, ngelixa ukwandisa ukuzinza kunye nokuhambelana kokucoca ibhetshi ukuya kwibhetshi, ngakumbi uvavanyo lokhuselo lokusingqongileyo, i-biopharmaceuticals, uvavanyo lokutya kunye neziyobisi kunye namanye amashishini.

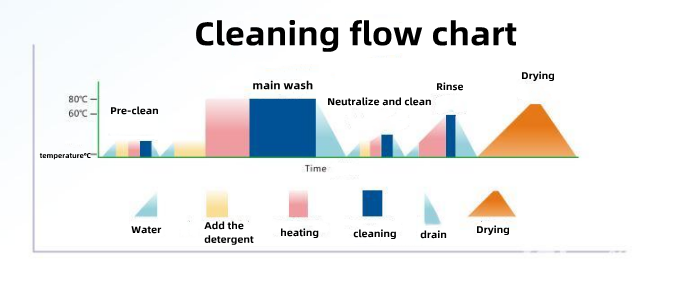

Iwasha yeglasi yokusebenza umgaqo-siseko:

Ngamanzi ompompo kunye namanzi acocekileyo (okanye amanzi athambileyo) njengendlela yokusebenza, usebenzisa i-arhente ethile yokucoca, eqhutywa yipompo yokujikeleza, ulwelo lokucoca luhlanjwe ngokuthe ngqo kwi-360 ° ngaphakathi nangaphandle kwesitya ngokujikeleza ingalo yokutshiza kunye nombhobho wokutshiza. , ukwenzela ukuba uhlambulule, u-emulsify kwaye uchithe izinto ezisele kwisitya phantsi kwesenzo samandla omatshini kunye neekhemikhali;Ukongeza, i-liquid yokucoca inokufudumeza ngokuzenzekelayo, kwaye ke izitya ziyakwazi ukutshisa kwaye zihlanjululwe nge-disinfected ukufezekisa umphumo ongcono wokucoca.Ukuba imodeli enomsebenzi wokomisa ikhethiwe, ibhotile yesampuli inokuba nomoya oshushu womisiwe emva kokuhlamba ukuphepha ukungcola okwesibini okubangelwa ukungasuswa ngexesha.

IWasher yeGlassware yeLabhoratri inokucoca ngokuzenzekelayo kunye nokomisa kunye neminye imisebenzi enqumlayo, kwaye yonke inkqubo yayo yokusebenza iqulunqwe ikakhulu ziinkqubo ezinkulu ezintathu, eziziswe ngolu hlobo lulandelayo:

1. Inkqubo yokubeka iliso kwi-intanethi

Ngethuba lenkqubo yokucoca, nokuba i-residu encinci kakhulu emanzini ahlambulukileyo inokuchaphazela kakhulu iziphumo zokucoca.I-washer yebhotile ibeka umsebenzi we-alamu yenkqubo, ukuba i-conductivity kwiseshoni yokugqibela yokucoca idlula ixabiso elimiselweyo lomthengi, izixhobo ziya kuhlamba ngokuzenzekelayo.Inkqubo entsha yokubeka iliso kwi-intanethi ye-conductivity yokugcinwa kwe-intanethi evela kwi-washer yeebhotile isusa imfuno yeendleko ezongezelelweyo zokulungiswa kunye nokulinganisa.Inkqubo ihlanganiswe kwindlela yokujikeleza kwamanzi kwaye ayinakho ukudibanisa ngokuthe ngqo kunye nenkqubo yamanzi, echanekileyo kakhulu.

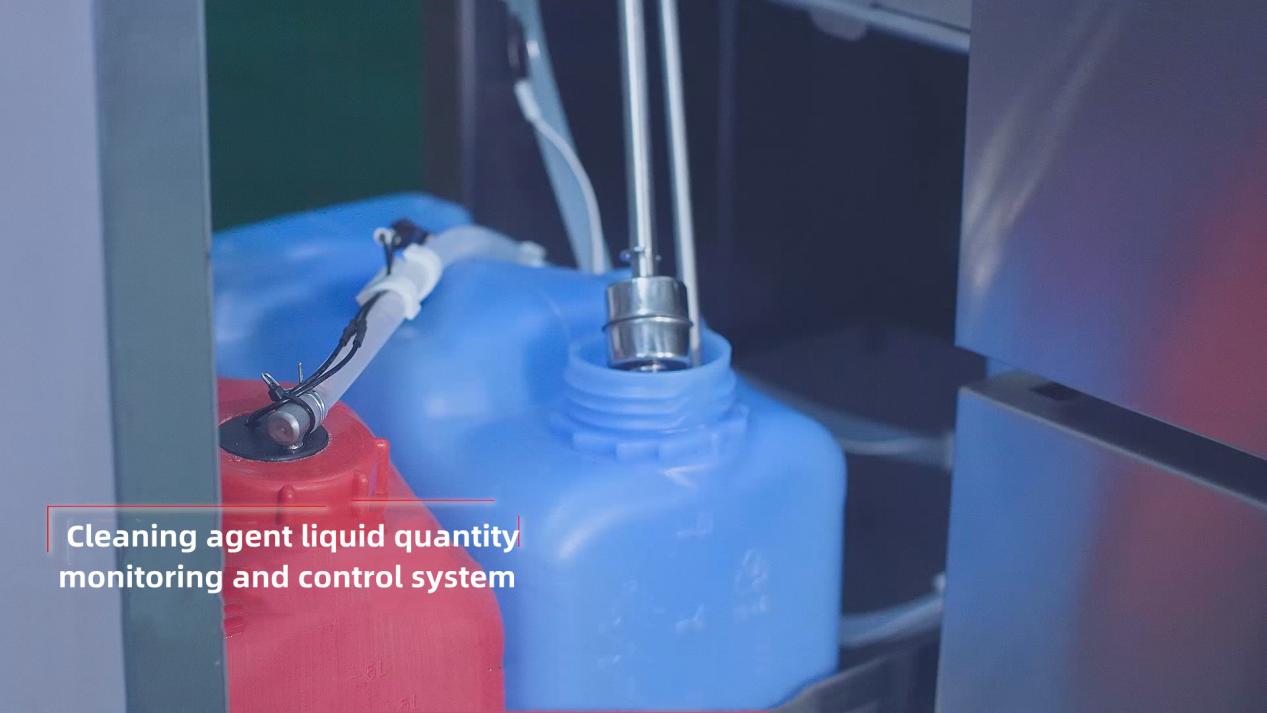

2. Ukucoca ulwelo lwe-arhente yokubeka iliso kunye nenkqubo yokulawula

I-arhente yokucoca umthamo womthamo wokubeka iliso kunye nenkqubo yokulawula yandisa ukhuseleko lwenkqubo.Xa usongeza ikhemikhali yesicoci, inkqubo ikhusela iziphumo ze-viscosity yolwelo kunye nobushushu be-ambient kwiimpawu zokuqukuqela kolwelo, ivumela ukuhanjiswa komthamo wolwelo oluchanekileyo ngakumbi.Indlela elula yokulawula i-flowmeter esetyenziswe kwixesha elidlulileyo yachaphazeleka yimiba yokusingqongileyo.Itekhnoloji entsha ye-washer yebhotile inokuchaneka okukhulu kunye nokhuseleko.

3. Ukutshiza inkqubo yokulawula izinga lokuhamba kwengalo

Ngomsebenzi wokucoca i-spray high-pressure, oko kukuthi, inkqubo yokulawula izinga lokungena kwengalo yokutshiza, ibhotile ye-Laboratory Washer inokuchonga ngokuzenzekelayo inkqubo yebhasikithi elayishiweyo, kwaye ilawule ngokuchanekileyo isantya sengalo yokutshiza kwigumbi lokucoca.Ukuba ukulayishwa kungalunganga, i-washer yebhotile ibona impazamo ekuqaleni kweprogram kwaye imisa umsebenzi.Ngethuba lenkqubo yokucoca, umatshini wokuhlamba ibhotile ufumanisa isantya sengalo yokutshiza ukuqinisekisa ukuba isantya siphakathi koluhlu olumiselweyo, ukuze kufezekiswe umphumo ongcono wokucoca.

Umatshini wokuhlamba weglasi yeempawu zeelebhu:

1. Ukuphakama kwesibiyeli esilungelelanisiweyo sokuqinisekisa ukucocwa okusebenzayo kweenkcazo ezahlukeneyo zezixhobo;

2. Ukulawula ubushushu bamanzi kabini ukuqinisekisa wonke ubushushu bamanzi okucoca;

3. Ulwelo lokucoca lunokusetwa kwaye longezwe ngokuzenzekelayo;

4. Emva kokucoca, inokomiswa kwi-situ;

5. Impompo yokujikeleza ephezulu ephuma ngaphandle, uxinzelelo oluzinzileyo noluthembekileyo lokucoca;

6. Lungiselela indawo yokucoca ngokomgaqo we-fluid mechanics ukuqinisekisa ukucoceka kwento nganye;

7. Ingalo yokutshiza ejikelezayo yoyilo oluphuculweyo lombhobho woxinaniso oluphezulu iqinisekisa ukuba isitshizi sigqunyiwe ngaphandle kwee-engile ezifileyo kwi-360 °.

Ixesha lokuposa: Mar-04-2022